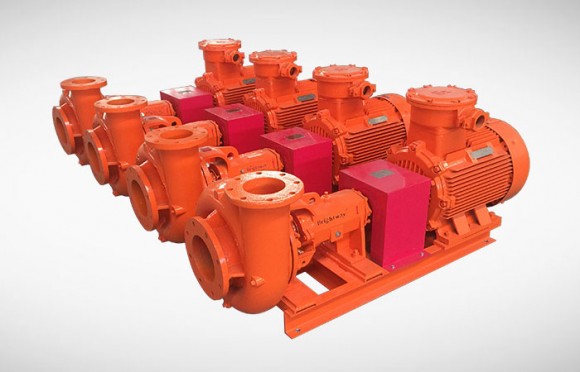

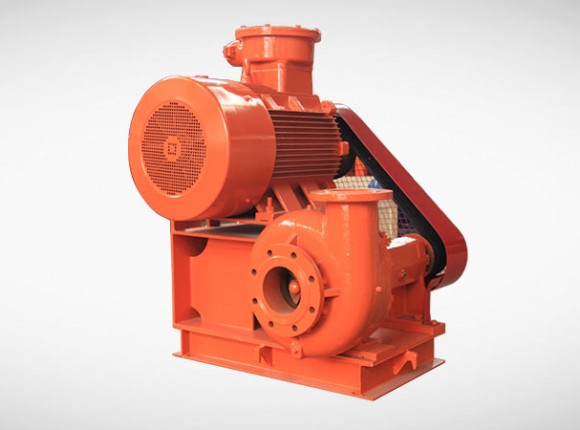

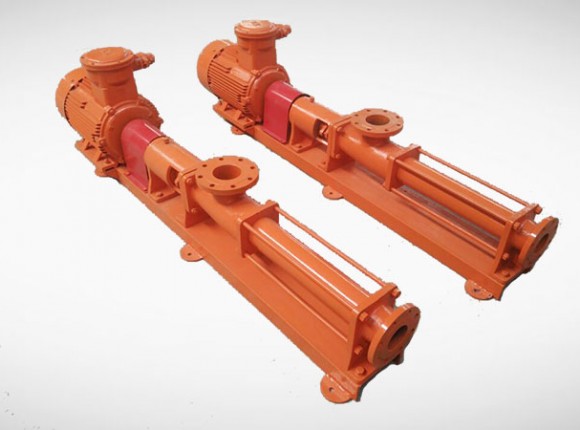

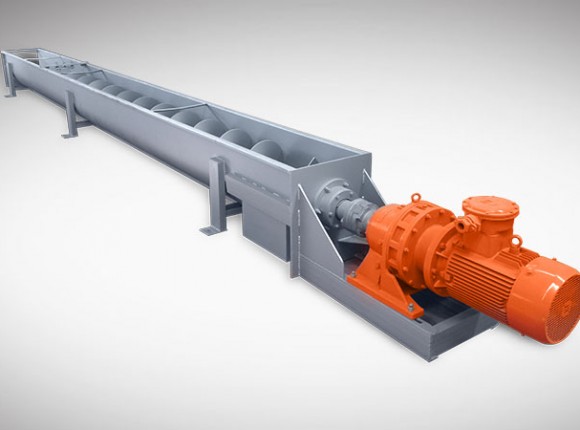

BWSB系列砂泵是为除砂器、除泥器、射流混浆装置提供动力的配套设备,也可作为泥浆泵辅助的灌注泵和井口的补给泵。其参数设计充分考虑配套的设备工作环境,大多数零件可以互换,具有可操作维护方便、轴封泄漏量少,工作运行可靠、使用寿命长等优点。

正道能源BWSB系列砂泵优势

1.泵体选用球铁HT250材质,叶轮选用高铬合金材质,结构优化,占用空间小。

2.密封件选用SS304不锈钢机械密封材质,密封效果好,环保,配件与美国米森泵能够完全互换。

3.噪音分呗小,无污染,运行平稳。

4.配套电机选用南阳防爆或其他国产品牌严格保证了产品质量的可靠及寿命。

5.泵体打磨、喷砂,环氧富锌底漆,环氧云铁中漆,聚氨酯面漆,采用高压无气喷涂设备施工,大大提高了产品自身表面的耐磨防腐及外观效果。

正道能源BWSB系列砂泵技术参数

【砂泵:1450转速规格】

| 型 号 | 叶轮直径 | 排量 | 扬程 | 转速 | 效率 | 容许气蚀 | 轴功率 | 推荐功率 |

|---|---|---|---|---|---|---|---|---|

| 单位 | (inch) | (m³/h) | (m) | (rpm) | (%) | (m) | KW | KW |

| BWSB10×8×14J | 14 | 410 | 33 | 1450 | 57 | 4 | 64.6 | 110 |

| BWSB10×8×14J | 13 | 380 | 26 | 1450 | 56 | 4 | 48 | 90 |

| BWSB10×8×14J | 12 | 370 | 18 | 1450 | 52 | 4 | 34.9 | 75 |

| BWSB8×6×14J | 13.5 | 265 | 40 | 1450 | 66 | 2.5 | 43.7 | 90 |

| BWSB8×6×14J | 12.5 | 255 | 32 | 1450 | 67 | 2.5 | 33.2 | 75 |

| BWSB8×6×14J | 11.5 | 250 | 24 | 1450 | 63 | 2.7 | 25.9 | 55 |

| BWSB8×6×14J | 11 | 245 | 20 | 1450 | 62 | 2.7 | 21.5 | 45 |

| BWSB8×6×11J | 11 | 220 | 23 | 1450 | 65 | 3 | 21.2 | 45 |

| BWSB8×6×11J | 10 | 210 | 17 | 1450 | 70 | 3 | 13.9 | 30 |

| BWSB6×5×14J | 12.5 | 200 | 34 | 1450 | 65 | 3.2 | 28.5 | 55 |

| BWSB6×5×14J | 12 | 195 | 31 | 1450 | 68 | 3 | 24.2 | 45 |

| BWSB6×5×14J | 11 | 190 | 24 | 1450 | 70 | 3.5 | 17.7 | 37 |

| BWSB6×5×11J | 11 | 190 | 23 | 1450 | 70 | 3 | 17 | 37 |

| BWSB5×4×14J | 12 | 110 | 32 | 1450 | 65 | 3.5 | 14.7 | 30 |

| BWSB5×4×14J | 11 | 105 | 27 | 1450 | 68 | 4 | 11.4 | 22 |

| BWSB5×4×14J | 10 | 100 | 21 | 1450 | 68 | 4.2 | 8.4 | 18.5 |

| BWSB5×4×14J | 9.5 | 95 | 17 | 1450 | 68 | 4.2 | 6.5 | 15 |

| BWSB4×3×13J | 11.5 | 90 | 30 | 1450 | 65 | 3.6 | 11.3 | 22 |

| BWSB4×3×13J | 11 | 85 | 27 | 1450 | 65 | 3.5 | 9.6 | 18.5 |

| BWSB4×3×13J | 10 | 80 | 21 | 1450 | 66 | 3.5 | 6.9 | 15 |

| BWSB4×3×13J | 9 | 70 | 16 | 1450 | 66 | 3.5 | 4.6 | 11 |

| BWSB3×2×13J | 11.5 | 60 | 27 | 1450 | 56 | 2.5 | 7.8 | 15 |

| BWSB3×2×13J | 11 | 50 | 25 | 1450 | 56 | 2.5 | 6.1 | 11 |

| BWSB3×2×13J | 10 | 45 | 21 | 1450 | 60 | 2.3 | 4.3 | 7.5 |

| BWSB3×2×10J | 9 | 40 | 16 | 1450 | 60 | 2.1 | 2.9 | 5.5 |

【砂泵:1750转速规格】

| 型 号 | 叶轮直径 | 排量 | 扬程 | 转速 | 效率 | 容许气蚀 | 轴功率 | 推荐功率 |

|---|---|---|---|---|---|---|---|---|

| 单位 | (inch) | (m³/h) | (m) | (rpm) | (%) | (m) | KW | KW |

| BWSB10×8×14J | 12.5 | 400 | 32 | 1750 | 52 | 4 | 67 | 132 |

| BWSB10×8×14J | 12 | 380 | 27 | 1750 | 50 | 4 | 55.9 | 110 |

| BWSB8×6×14J | 11.5 | 260 | 36 | 1750 | 55 | 2.5 | 46.3 | 90 |

| BWSB8×6×14J | 11 | 250 | 30 | 1750 | 53 | 2.5 | 38.5 | 75 |

| BWSB8×6×11J | 11 | 250 | 35 | 1750 | 67 | 3 | 35.6 | 75 |

| BWSB8×6×11J | 10 | 240 | 26 | 1750 | 67 | 3 | 25.4 | 55 |

| BWSB6×5×14J | 11.5 | 200 | 42 | 1750 | 70 | 3.2 | 32.7 | 75 |

| BWSB6×5×14J | 11 | 190 | 37 | 1750 | 68 | 3 | 28.1 | 55 |

| BWSB6×5×14J | 10 | 180 | 29 | 1750 | 65 | 3 | 21.9 | 45 |

| BWSB6×5×11J | 11 | 190 | 35 | 1750 | 70 | 3 | 25.9 | 55 |

| BWSB6×5×11J | 10 | 180 | 28 | 1750 | 70 | 3 | 19.6 | 45 |

| BWSB6×5×11J | 9.5 | 170 | 25 | 1750 | 68 | 3 | 17 | 37 |

| BWSB5×4×14J | 11 | 105 | 38 | 1750 | 62 | 3.5 | 17.5 | 37 |

| BWSB5×4×14J | 10.5 | 105 | 34 | 1750 | 62 | 3.5 | 15.7 | 30 |

| BWSB5×4×14J | 9.5 | 100 | 25 | 1750 | 62 | 4.5 | 11 | 22 |

| BWSB5×4×14J | 9 | 95 | 21 | 1750 | 62 | 3.5 | 8.8 | 18.5 |

| BWSB5×4×14J | 8.5 | 90 | 17 | 1750 | 62 | 4.5 | 6.7 | 15 |

| BWSB4×3×13J | 11 | 85 | 40 | 1750 | 64 | 3.5 | 14.5 | 30 |

| BWSB4×3×13J | 10 | 80 | 32 | 1750 | 64 | 3.5 | 10.9 | 22 |

| BWSB4×3×13J | 9 | 75 | 24 | 1750 | 64 | 3.5 | 8.8 | 18.5 |

| BWSB4×3×13J | 8.5 | 70 | 21 | 1750 | 64 | 3.5 | 6.3 | 15 |

| BWSB3×2×13J | 10 | 50 | 30 | 1750 | 58 | 2.5 | 7 | 15 |

| BWSB3×2×13J | 9.5 | 45 | 27 | 1750 | 58 | 2.3 | 5.7 | 11 |

| BWSB3×2×13J | 8.5 | 40 | 23 | 1750 | 58 | 2.1 | 4.3 | 7.5 |

如果您对我们的”砂泵”产品有兴趣,您可以拨打我们的电话了解报价信息!我们会及时给您回复!